BLUETEC technology is making Mercedes-Benz the pioneer of a new generation of clean and powerful high-tech vehicles with highly effective exhaust gas treatment systems that give them the potential to fulfill the world’s most stringent emission limits in the future. At the same time, the basic technology for turbocharging and common-rail direct injection used in Mercedes CDI diesel engines has already proved itself in millions of vehicles in Europe.

BLUETEC technology is making Mercedes-Benz the pioneer of a new generation of clean and powerful high-tech vehicles with highly effective exhaust gas treatment systems that give them the potential to fulfill the world’s most stringent emission limits in the future. At the same time, the basic technology for turbocharging and common-rail direct injection used in Mercedes CDI diesel engines has already proved itself in millions of vehicles in Europe.

BLUETEC ensures that diesels will continue to offer outstanding driving pleasure in the future, especially in the U.S. What’s more, in view of continually rising fuel prices, BLUETEC represents the best choice for both today and tomorrow.

High Performance, High Fuel Mileage and Long Cruising Range

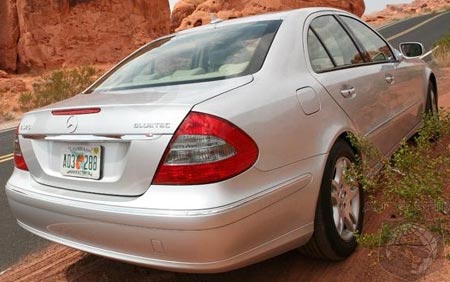

The Mercedes-Benz E320 BLUETEC offers outstanding driving dynamics, unprecedented efficiency and impressive environmental compatibility. Its three-liter V6 engine combines the powerful torque of a large V8 engine with the low fuel consumption of a four-cylinder compact. The E320 BLUETEC accelerates from zero to 60 mph in just 6.6 seconds, making it one of the sportiest luxury sedans on the market.Â

Its tremendous torque of 3881 lb-ft exceeds most V8-powered models. At the same time, the Mercedes- Benz E320 BLUETEC achieves 35 miles per gallon (6.7 liters/100 km) in combined cycle driving – a level of fuel efficiency normally found only in a compact car. The full-size E-Class vehicle is also environmentally friendly as a result of its excellent fuel economy and extremely low emissions.

The BLUETEC concept utilizes state-of-the-art diesel engines featuring common-rail direct injection, thereby providing all the benefits this drive system has to offer. Fuel consumption in these diesel vehicles is 20to 40 percent lower than in cars equipped with a comparable gasoline engine, and torque — the key indicator ofengine power — is 30 to 50 percent higher.

The E320 BLUETEC offers an impressive example of such attributes: its torque of 388 lb-ft gives it the power of a large V8 gasoline engine, and its acceleration from 0 to 60 mph in just 6.6 seconds is an illustrationof the model’s outstanding performance. The vehicle’s combination of high torque and unbelievably good fueleconomy appeals to U.S. consumers, who value good acceleration, relaxed cruising and long range (700 miles or more) between refueling stops.

Its fuel economy rating of 37 mpg (6.4 liters/100 km) on the highway, and 26 mpg (9.0 liters/100 km) in the EPA city cycle are higher than many models in the compact class. The BLUETEC system also performs well against hybrid technology, as the standard fuel economy ratings for the Mercedes-Benz E320 BLUETEC are better than those for a hybrid of a comparable size and power.Â

The benefits offered by such advanced diesel engines become even more apparent in actual driving, in part because diesel fuel consumption in real-life driving generally remains very close to fuel economy ratings, and is sometimes even better – not usually the case with other drive systems. Diesels have in fact performed extremely well in comparative independent tests of diesel and hybrid vehicles conducted by journalists from automotive magazines on three different continents. In each case, whether driving straigh across the U.S., Germany or Japan, the fuel consumption of diesel vehicles was significantly lower than that of hybrid cars.Â

New Diesel Fuel Has 97 Percent Less Sulfur

The use of BLUETEC in the U.S. is made possible by the introduction of cleaner, ultra-low-sulfur diesel containing less than 15 ppm sulfur content, and the new fuel becomes available across the U.S. and Canada in October 2006. Since the previous sulfur content in diesel fuel was 500 ppm, sulfur is now reduced by 97 percent, which will provide noticeable lower emissions for all diesel vehicles.Â

Sulfur, a natural part of crude oil, is one of the key causes of particulates. The introduction of ultra-low sulfur diesel has now made it possible to use particulate filters in the U.S. What’s more, this fuel will enable efficient aftertreatment of nitrogen oxide emissions. The fuel for the world’s cleanest diesel is now available, and the Mercedes-Benz E320 BLUETEC’s ability to travel more than 700 miles (approx. 1,200 km) on a singletank of fuel means its drivers won’t have to go looking for fuel stations very often.

Rather than being an isolated solution, the E320 BLUETEC is a key part of DaimlerChrysler’s overall strategy of ensuring sustainable mobility for the future. In various markets, the 3.0-liter diesel engine is used inten different Mercedes-Benz model lines. BLUETEC technology will be initially launched in the U.S. with theE320 BLUETEC, after which Mercedes-Benz will prepare for its introduction to other markets. BLUETEC willalso be made available in a passenger car model in Europe beginning in 2008.

DaimlerChrysler does not plan torestrict the use of BLUETEC to the Mercedes-Benz brand alone – the Jeep Grand Cherokee BLUETEC concept car, for example, represents another possibility for the future.

BLUETEC — The Market

Mercedes-Benz is considered to be the pioneer of automotive diesel technology – the Mercedes-Benz 260D, which was launched 70 years ago, was the world’s first production diesel car. Over the years, Mercedes-Benz has consistently used its innovation and engineering talent to enhance and improve the internal combustion system invented by Rudolf Diesel. Mercedes also has a great diesel tradition in the U.S. that stretches back more than 40 years. The most successful diesel phase to date for the brand was during the 1980s, when diesel passenger cars accounted for up to 80 percent of total Mercedes-Benz sales in the U.S.

As a result, Mercedes-Benz not only has a longer history of diesel expertise than any other automaker, but also understands the U.S. diesel market well. In August 2002, during a time when it appeared that diesel passenger cars had practically no future in the U.S., Mercedes-Benz laid the cornerstone for a new era of diesel success by introducing the current-generation E-Class line. Then, in January 2004, the brand officially launched diesel’s U.S. comeback at the Detroit Auto Show with the E320 CDI, which went on sale in April 2004. Stateof-the-art common-rail direct injection, a turbocharger with variable turbine geometry and an intercooler made the E320 CDI much stronger, quieter and cleaner than any diesel that had ever come before it. Sales of the E320 CDI have risen sharply since fuel prices began escalating in August 2005, and more than 11,000 E-Class dieselpowered vehicles have been sold in the U.S. since the market launch in April 2004.

Market analysts agree that diesel vehicles will continue to become more popular. Automotive Industry

Data, for example, predicts that diesel vehicles will account for nearly 60 percent of passenger cars in Western Europe in 2009, while J.D. Power expects the diesel share of western European passenger cars to rise to around 56 percent over the medium term.

Diesel market shares around the world are fundamentally influenced by fuel prices. The more expensive fuel becomes, the higher the market share for fuel-efficient diesels. Fuel prices have traditionally been lower in the U.S. than elsewhere in the world, and this in part explains why diesel’s share of vehicle registrations in the U.S. is still comparatively low. Another explanation is offered by the fact that no sulfur-free fuel has been available up until now, and such fuel is indispensable for state-of-the-art diesel technology.

U.S. Diesel Sales Up 40 Percent

Few have noticed that diesel car and light truck sales have risen 40 percent in the U.S. over the last five years, perhaps because the sales volume was rather low to begin with. Still, more than 550,000 diesel passenger cars and light trucks were sold in the U.S. in 2005, an increase of nine percent over 2004. Diesel market share in the U.S. reached 3.5 percent in 2005. Light trucks sales, which make up nearly half the U.S. vehicle market, included nearly six percent diesel vehicles last year.

Forecasts regarding the diesel share of the U.S. market in the future are optimistic. An extensive study conducted by J.D. Power, for example, predicts that the market share of diesel vehicles in the U.S. will increase from 3.5 percent in 2005 to more than 15 percent in 2015. Automotive Industry Data also forecasts that diesel vehicles will account for more than 15 percent of the market in the U.S. over the long term.Â

This will be important for the U.S. because diesel vehicles can offer huge fuel savings potential if their market share is increased. This was confirmed in a study conducted by the U.S. Environmental Protection

Agency in 2004. Margo Oge, head of its Office of Transportation and Air Quality, concluded that if only onethird of all light-duty trucks in the U.S. were operated with modern diesel engines, the country would save 1.4 million barrels of oil per day – equal to the amount of oil the U.S. currently imports from Saudi Arabia.

Fuel costs and — more importantly — the huge improvements made to the performance and comfort offered by modern diesel engines, have led to a tremendous increase in the market share for diesel vehicles in Europe over the past few years. While diesel vehicles accounted for 32 percent of new registrations in Western Europe in 2000, that figure had risen to 49.5 percent by 2005, meaning that nearly half of all new automobiles in the region are now diesel-powered. The diesel share for SUVs is between 80 and 100 percent around the world, and upper-range vehicles such as the Mercedes-Benz E-Class represent another segment in which diesels perform well.

BLUETEC — A Modular Technology

BLUETEC is a modular concept that utilizes several coordinated technical measures to minimize emissions within the engine and also provide for effective exhaust gas treatment downstream. The process involves consistently reducing all relevant emission components to a minimum. The system for passenger cars includes an oxidation catalytic converter and a particulate filter in addition to new techniques for reducing nitrogen oxide emissions.

BLUETEC technology is especially important for lowering nitrogen oxide emissions, which is the last type of exhaust gas that’s higher in diesel vehicles than gasoline engines. Until recently, the only real remaining disadvantage of diesel engines as compared to gasoline engines was in the area of particulates and nitrogen oxides. However, Mercedes-Benz set the standard for modern diesel drive systems in the fall of 2003, when it introduced the maintenance-free particulate filter in Europe as part of the EU4 emission standards. Despite reducing diesel emissions by 75 percent over the past 15 years, the company is going further.Â

The mission is clear — through the use of innovative BLUETEC technology, diesel engines from Mercedes-Benz have the potential to meet the world’s most stringent emission standards. When this has been achieved, Mercedes-Benz will be able to offer the world’s cleanest diesels in every vehicle class.

The key aspect of the innovative BLUETEC technology involves lowering levels of nitrogen oxides (denoxification) in an effective and economical manner. In order to combine all technical solutions for emission reduction into an optimized package, Mercedes-Benz is implementing a multi-staged plan consisting of the following measures:

• Optimization of engines and combustion processes to reduce engine-out emissions as much as possible. This includes the use of electronic engine control systems, four-valve technology, third-generation common-rail direct injection with piezo injectors, variable-geometry turbochargers and exhaust gas recirculation.

• Use of oxidation catalytic converters to minimize emissions of carbon monoxide (CO) and unburned hydrocarbons (HC).

• Use of the particulate filter, which has been standard equipment in all Mercedes-Benz diesel passenger cars in many countries since the summer of 2005, cuts particulate emissions by up to 98%. This filter has led to particulate emissions significantly lower than the current EU4 limit of 0.025 grams/kilometer.

• The diesel engine inherently produces higher nitrogen oxides than a gasoline engine. However, BLUETEC can reduce nitrogen oxides so well that the vehicle can comply with the most stringent exhaust gas limits.

The E320 BLUETEC uses a refined NOx storage catalytic converter in combination with an SCR catalytic converter to lower nitrogen oxide emissions.

AdBlue Injection – Another Big Step

In future models, BLUETEC can add one more module — AdBlue injection, which involves the selective catalytic reduction (SCR) process. This is currently the most effective method for exhaust gas treatment, enabling nitrogen oxide emissions to be reduced by up to 80 percent. BLUETEC with AdBlue is currently being developed for production cars and will be used primarily in large vehicles and SUVs. The Mercedes Vision GL 320 BLUETEC concept car, for example, is currently the worlds cleanest and most fuelefficient SUV in its class. Regardless of the vehicles in which it is used, BLUETEC can comply with the world’s most stringent emission limits, including the BIN 5 standard that will go into effect in the U.S. in 2009.

The SCR process involves injecting AdBlue, an aqueous carbamide solution, into the exhaust flow, which releases ammonia (NH3), reducing nitrogen oxides to harmless nitrogen and water in the downstream SCR catalytic converter. Because only 0.1 liters of AdBlue is needed on average for every 100 kilometers driven (the equivalent of one to three percent of diesel consumption), its tank only needs to be refilled during regular maintenance checks. Achieving the greatest reduction of nitrogen oxides involves adding just the right amount of AdBlue for a given engine load and speed.

BLUETEC technology has been used successfully in more than 25,000 commercial vehicles from Mercedes-Benz since 2005, and three thousand locations in Europe now offer AdBlue. In fact, BLUETEC has decreased nitrogen oxide emissions to such an extent that the trucks already produce lower emissions than required by 2009 standards. As a result, Euro 5 trucks are entitled to pay lower road tolls in Germany at least until 2009.

Early on, DaimlerChrysler decided to use SCR-based BLUETEC technology to meet the Euro 4 and Euro 5 limits for commercial vehicles, and also to meet even more stringent European emissions standards in the future. All European manufacturers have since followed suit and are now developing technologies based on SCR to ensure compliance with Euro 5.Â

The Challenge For The Future: Sustainable Mobility

Fossil fuels are a finite resource, which is why ensuring sustainable mobility is the most important challenge for the future. The situation is made more urgent by the fact that the energy consumption is rising around the globe, which means the amount of carbon dioxide released into the atmosphere is also increasing. It’s clear that automobile manufacturers must work to reduce the consumption of fossil fuels and the emissions they produce, and also develop alternatives for the future. A large share of the 5.6 billion Euros that DaimlerChrysler spends each year on research and development goes toward achieving this goal.

At the same time, the company is convinced that this goal can only be achieved through an integrated approach that addresses mobility as a complete system — one which begins with the vehicle but also includes the fuels and transport infrastructure.

The fact is that consumption and emissions can only be further reduced in combination with optimized fuels. Cleaner fuels can already be used today in existing fleets to help significantly lower emissions. The current focus is on promoting the global introduction of low-sulfur fuels to enable the development of cleaner and more economical drive systems.

Biogenic fuels represents the dawn of a system of mobility practically free of CO2 emissions. When burned, such fuels generate only as much carbon dioxide as the plants used to make them absorbed from the air.

Biodiesel, which is made from vegetable oils, offers advantages over petroleum diesel. The same is true of bioethanol, which can be made from wheat, corn, or sugar cane. So-called Flex-Fuel vehicles, which can be operated with an 85-percent bioethanol-gasoline mix, will play an increasingly important role in the U.S., and

DaimlerChrysler already has 1.5 million such vehicles on the road. In fact, all 2007 Mercedes-Benz C230 sedans are flex-fuel vehicles, which come with special fuel lines as well as an in-line fuel sensor that allows the engine management system to make adjustments automatically for E85 ethanol and gasoline.

However, biomass-to-liquid fuels (BTL) such as SunDiesel have the best prospects for future success, and DaimlerChrysler has been working extensively on the development and production of such fuels for years.Â

A partnership between DaimlerChrysler, Volkswagen, CHOREN and Shell is now developing and testing SunDiesel in vehicles in Germany.

The fuel is made from scrap wood, but actually any kind of biomass can be used to produce it. The ecological balance shows that the use of SunDiesel leads to emissions approximately 90 percent lower than those produced by conventional fuels. Tests conducted by DaimlerChrysler have also confirmed the fuel’s excellent quality, and plans now call for filling new diesel passenger cars with SunDiesel at the factory as soon as the fuel becomes available in sufficient quantities.

DaimlerChrysler’s commitment to clean drive systems and to renewable, environmentally friendly fuels is a key element of the Group’s strategy for the future, with the overall goal of achieving sustainable mobility. Doing so will involve addressing three dimensions — the economy, the environment and society.

The latest Sustainability Report provides a closer look at DaimlerChrysler’s research and development activities and at the links between environmental protection, social responsibility and economic prosperity. [AutoSpies Press Release]